Addressing Challenges in Tire Transportation and Distribution Logistics Efficiency

world 7.com, mahadev book login id and password, silver exchange demo id:Addressing Challenges in Tire Transportation and Distribution Logistics Efficiency

In the world of logistics, transportation and distribution of tires pose unique challenges. Tires are essential components of vehicles, and their timely and efficient delivery is crucial for both manufacturers and consumers. However, several factors can hinder the smooth flow of tire transportation and distribution logistics. In this blog post, we will explore some of the key challenges in this industry and discuss strategies to address them.

1. Inventory Management: One of the primary challenges in tire transportation and distribution logistics is managing inventory effectively. Tires come in various sizes, types, and brands, making it crucial to have accurate inventory records to ensure the right tires are shipped to the right locations.

2. Transportation Costs: Shipping tires can be expensive due to their size and weight. Finding cost-effective transportation solutions is essential to reduce overhead costs and improve profit margins.

3. Warehouse Efficiency: Efficient warehouse operations are crucial for timely delivery of tires. Ensuring that warehouses are organized and optimized for quick order processing can help streamline distribution logistics.

4. Demand Forecasting: Accurately predicting demand for tires can be challenging, leading to overstocking or understocking issues. Implementing advanced forecasting techniques can help address this challenge and improve inventory management.

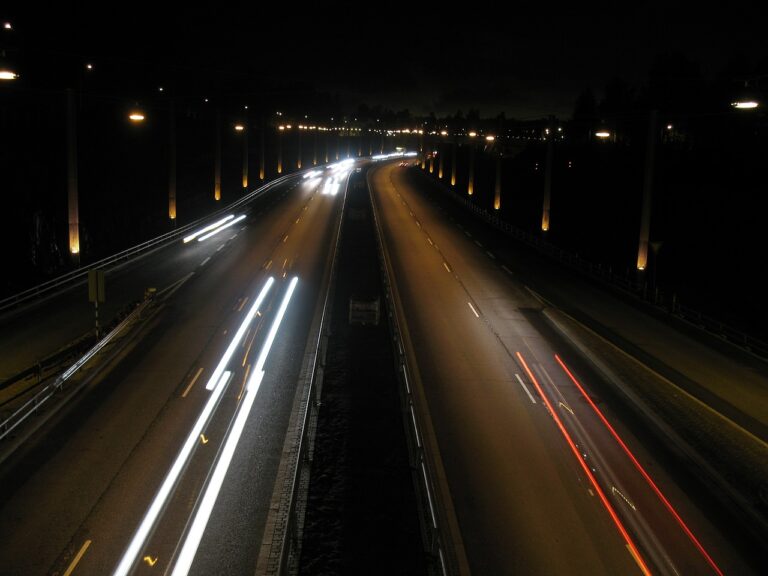

5. Last-Mile Delivery: The final leg of tire distribution, known as last-mile delivery, can be complex and costly. Finding efficient ways to deliver tires to customers’ doorsteps while reducing delivery times and costs is crucial for customer satisfaction.

6. Compliance and Regulations: The tire industry is subject to various regulations and compliance requirements, such as safety standards and environmental regulations. Ensuring compliance with these regulations is essential for avoiding penalties and maintaining a positive brand image.

To address these challenges and improve tire transportation and distribution logistics efficiency, companies can implement the following strategies:

1. Invest in Technology: Utilizing advanced technology such as warehouse management systems, inventory tracking software, and route optimization tools can help streamline operations and improve efficiency.

2. Collaboration with Third-Party Logistics Providers: Partnering with experienced third-party logistics providers can help companies leverage their expertise and resources to optimize transportation and distribution processes.

3. Implement Just-In-Time Inventory Management: Adopting a just-in-time inventory management approach can help companies reduce inventory holding costs while ensuring timely delivery of tires to customers.

4. Optimize Warehouse Layout: Designing warehouses for maximum efficiency and implementing lean principles can help improve order picking and packing processes, reducing fulfillment times.

5. Enhance Communication: Effective communication between different stakeholders in the supply chain is crucial for seamless tire transportation and distribution logistics. Implementing communication tools and protocols can help improve coordination and collaboration.

6. Continuous Improvement: Regularly evaluating and optimizing logistics processes is essential for staying competitive in the tire industry. Companies should continuously seek ways to enhance efficiency, reduce costs, and improve customer satisfaction.

By addressing these challenges and implementing the strategies mentioned above, companies in the tire industry can improve transportation and distribution logistics efficiency, reduce costs, and enhance customer satisfaction.

FAQs

1. What are the common challenges in tire transportation logistics?

The common challenges in tire transportation logistics include inventory management, transportation costs, warehouse efficiency, demand forecasting, last-mile delivery, and compliance with regulations.

2. How can companies improve tire distribution logistics efficiency?

Companies can improve tire distribution logistics efficiency by investing in technology, collaborating with third-party logistics providers, implementing just-in-time inventory management, optimizing warehouse layout, enhancing communication, and continuously improving processes.

3. Why is last-mile delivery important in tire distribution logistics?

Last-mile delivery is crucial in tire distribution logistics because it is the final step in delivering tires to customers’ doorsteps. Ensuring efficient last-mile delivery is essential for customer satisfaction and loyalty.

4. How can companies address compliance and regulatory challenges in the tire industry?

Companies can address compliance and regulatory challenges in the tire industry by staying informed about relevant regulations, implementing robust compliance processes, and conducting regular audits to ensure adherence to standards.

5. What role does demand forecasting play in tire distribution logistics?

Demand forecasting plays a significant role in tire distribution logistics by helping companies predict customer demand accurately, reduce overstocking or understocking issues, and optimize inventory levels for efficient distribution.