Industry Insights: Strategies for Implementing Circular Economy Practices in Tire Production

11xplay reddy login password, tigerexch247, betbook 1:The concept of a circular economy is gaining traction across various industries as a way to reduce waste and promote sustainability. In the tire production industry, implementing circular economy practices can help companies minimize their environmental impact while also creating new opportunities for innovation and efficiency. In this article, we will explore some strategies for implementing circular economy practices in tire production.

Understanding the Circular Economy

Before diving into specific strategies, it’s essential to have a solid understanding of what a circular economy entails. The circular economy is a regenerative system in which resources are kept in use for as long as possible, extracting the maximum value from them while in use and recovering and regenerating products and materials at the end of their life cycle. This contrasts with the traditional linear economy model of take-make-waste, which results in significant waste and environmental degradation.

By embracing the principles of the circular economy, tire producers can reduce their dependence on virgin resources, lower production costs, and minimize environmental impact. With that in mind, let’s delve into some strategies for implementing circular economy practices in tire production.

1. Design for Durability and Recyclability

One of the key principles of the circular economy is designing products for durability and recyclability. In the case of tire production, this means creating tires that are long-lasting, easy to repair, and simple to recycle at the end of their life cycle. By using high-quality materials and innovative design techniques, companies can extend the lifespan of their tires and reduce the need for frequent replacements.

Additionally, incorporating recyclable materials into tire production can make it easier to recover and repurpose worn-out tires, creating a closed-loop system that minimizes waste. Designing tires with easily separable components can also facilitate recycling and reusing valuable materials, such as rubber and steel.

2. Implement Sustainable Sourcing Practices

Sustainable sourcing is another critical component of the circular economy. Tire producers can work with suppliers who adhere to environmentally responsible practices, such as sourcing rubber from sustainable plantations and using recycled steel in tire manufacturing. By ensuring that raw materials are ethically sourced and environmentally friendly, companies can reduce their carbon footprint and promote sustainable production practices throughout the supply chain.

Moreover, investing in local sourcing can help minimize transportation emissions and support local economies, creating a more sustainable and resilient production system. By prioritizing suppliers who share their commitment to sustainability, tire producers can build a more robust and environmentally conscious supply chain.

3. Embrace Retread and Remanufacturing Technologies

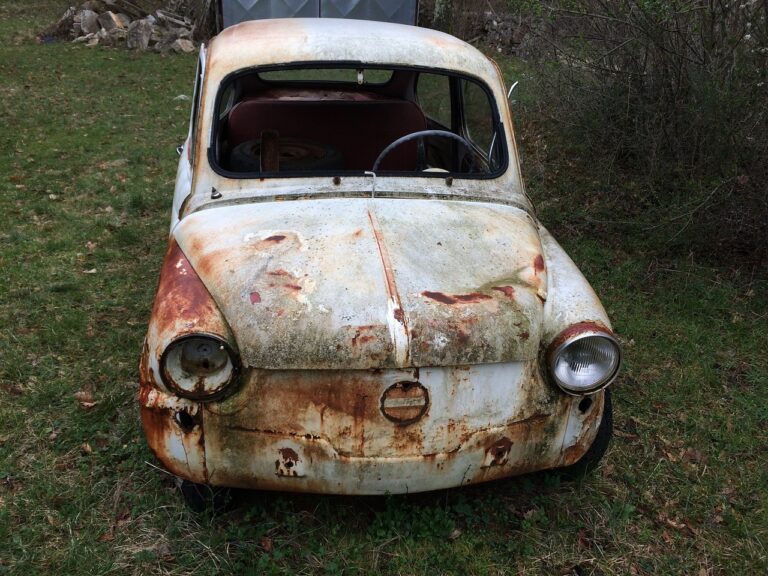

Retreading and remanufacturing are cost-effective and sustainable alternatives to producing new tires from scratch. These processes involve refurbishing worn-out tires by replacing the tread and other components, extending their lifespan and reducing the need for new tire production. By investing in retread and remanufacturing technologies, tire producers can lower production costs, conserve resources, and reduce waste.

Furthermore, retread and remanufacturing technologies can significantly reduce the environmental impact of tire production by diverting used tires from landfills and minimizing energy consumption. Companies that embrace these practices can position themselves as leaders in sustainable manufacturing and attract environmentally conscious consumers looking for eco-friendly products.

4. Establish Take-Back Programs and Recycling Initiatives

Take-back programs and recycling initiatives are essential for closing the loop on tire production and promoting a circular economy. By offering customers a convenient way to return their worn-out tires, companies can collect used tires for recycling and repurposing, reducing waste and conserving valuable materials. Establishing partnerships with recycling facilities and waste management companies can help streamline the collection and recycling process, making it easier for customers to participate in sustainable practices.

Additionally, tire producers can explore innovative recycling technologies, such as pyrolysis and devulcanization, to recover materials from old tires and create new products. By investing in these advanced recycling methods, companies can unlock new opportunities for resource recovery and waste reduction, enhancing the sustainability of their production processes.

5. Educate Consumers and Foster a Culture of Sustainability

Educating consumers about the benefits of sustainable tire production is essential for driving widespread adoption of circular economy practices. Tire producers can engage with customers through marketing campaigns, social media outreach, and educational materials to raise awareness about the environmental impact of tire production and the importance of recycling and responsible consumption.

Moreover, fostering a culture of sustainability within the organization and the industry can help companies align their values with those of environmentally conscious consumers and stakeholders. By prioritizing sustainability in decision-making processes, investing in green technologies, and collaborating with like-minded partners, tire producers can demonstrate their commitment to creating a more sustainable and circular economy.

FAQs

Q: What are the benefits of implementing circular economy practices in tire production?

A: Implementing circular economy practices in tire production can help companies reduce waste, lower production costs, minimize environmental impact, and create new opportunities for innovation and efficiency. By designing durable and recyclable tires, embracing sustainable sourcing practices, investing in retread and remanufacturing technologies, establishing take-back programs, and educating consumers about sustainable practices, tire producers can promote a more sustainable and circular economy.

Q: How can consumers contribute to a circular economy in the tire industry?

A: Consumers can contribute to a circular economy in the tire industry by purchasing durable and recyclable tires, participating in take-back programs, and properly disposing of their worn-out tires. By choosing eco-friendly products, supporting companies that prioritize sustainability, and advocating for responsible consumption, consumers can help drive the transition towards a more sustainable and circular economy.

In conclusion, implementing circular economy practices in tire production can bring a host of benefits for companies, consumers, and the environment. By designing durable and recyclable tires, embracing sustainable sourcing practices, investing in retread and remanufacturing technologies, establishing take-back programs, and educating consumers about sustainable practices, tire producers can create a more sustainable and resilient production system. By working together towards a circular economy, the tire industry can pave the way for a greener and more sustainable future.